MICO PMDC Motor Instruction Manual

MICO PMDC MOTOR

Instruction Manual

1. Application

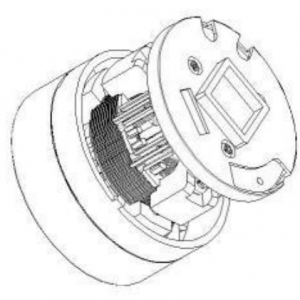

The ZYT series permanent magnet DC motor utilizes ferrite permanent magnet excitation and is of the enclosed self-cooling type. It features small size, light weight, reversible speed, and wide range of applications. As a low-power DC motor, it can be used as a driving component in various devices.

2. This series of motors can be manufactured in the installation styles shown in Table 1

TABLE 1

|

Installation Style |

Code Of Installation Style |

Base No. |

|

|

Single Shaft |

Dual Shaft |

||

|

Installation of outer circle of casing |

A5 |

AA5 |

55~130 |

|

End cap flange installation |

A3 |

AA3 |

55~130 |

|

Foot mounting |

A1 |

AA1 |

90-130 |

3. This series of motors is enclosed and self-cooled, and is allowed to operate under the following conditions:

(1) Altitude not exceeding 4000 meters;

(2) Ambient temperature: -25℃~+40℃;

(3) When the relative air humidity is 95% (+20℃)

(4) For any installation location, the brush life is 2000 hours at speeds of 3000 rpm and below; the brush life is 1500 hours at speeds of 6000 rpm and above.

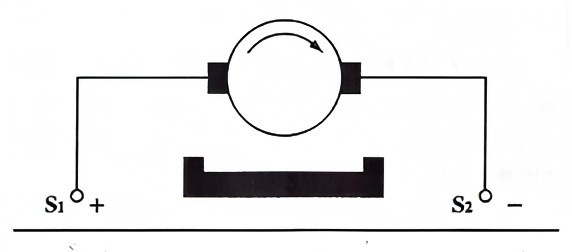

4. Electrical wiring diagram: (viewed from the commutator end)

5. Use and maintenance

(1)The room where the motor is stored should be dry and clean.

(2)The motor has been adjusted at the manufacturing plant. Unless necessary, do not loosen the fastening screws and knobs.

(3)Before using the motor, the shaft extension must be carefully wiped with clean gasoline. The mounting frame that fits with the motor and the base should be made of non-magnetic material. During installation, do not knock any part and check whether the motor performance is normal.

(4)Before operating the motor, it is necessary to check the correctness of the wiring and the reliability of the contact, as well as inspect the concentricity of the motor and the reliability of the connection.

(5)When starting a motor, it is not advisable to directly start the armature at full voltage, especially for motors with higher speeds and larger sizes.

(6)The motor cannot operate under overload conditions.

(7)The surface of the motor commutator should be kept clean, and it should be cleaned with a cleaning cloth dampened with clean alcohol or gasoline as needed or after 100 hours of operation.

(8)When the effective height of the brush wears down to the size specified in Table 2, or when the motor's operation is abnormal due to the brush, the brush should be replaced. After replacing the new brush, the motor must be run without load for 5 hours to grind the brush. After grinding, the commutator surface should also be wiped clean with a clean cloth dampened with clean alcohol or gasoline, and a rated load test should be conducted. At this time, the commutation spark should not exceed level 1.5. If it is qualified, the motor can work normally.

TABLE 2

|

Base # |

55 |

70 |

90 |

110 |

130 |

|

Effective height of electric brush |

5 |

6 |

7 |

7 |

10 |

(9)The inner surface of the motor brush holder box should be kept clean to prevent brush powder from sticking. If necessary, or after 100 hours of operation, it should be wiped with a clean cloth dampened with clean alcohol or gasoline.

(10)The bearing grease is designated as No. 7007 general aviation grease. After the motor runs continuously at full load for 500 hours, the grease should be replaced. The amount of grease is generally 0.5 of the bearing chamber space, and the interior of the motor should be cleaned.

(11)When the motor is not in use, the shaft extension should be coated with industrial Vaseline for rust prevention, and then covered with a protective sleeve before being resealed.

(12)The bearing models and brush grades used in the base-type products of various frame sizes are listed in Table 3.

TABLE 3

|

Base # |

Bearing |

Brush |

Remark |

||

|

Commutator end |

Drive End |

≤48V |

>48V |

||

|

55ZYT |

E60025 |

E60026 |

J220 |

S4 |

|

|

70ZYT |

E60026 |

E60027 |

J220 |

S4 |

|

|

90ZYT |

E60029 |

E60029 |

J220 |

S4 |

|

|

110ZYT |

E60200 |

E60202 |

|

S4 |

|

|

130ZYT |

E60204 |

E60203 |

|

S4 |

|

Due to the high precision requirements for brush dimensions, if the motor needs to be replaced with a new brush, users can order it from our factory based on the specific motor model.