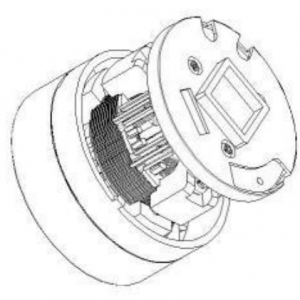

Custom DC Motor

Custom DC Motor Solutions: The Key to High-Efficiency Motion Systems in Modern Engineering

In today’s rapidly evolving manufacturing landscape, customized components are no longer optional—they are essential. Among them, the custom DC motor has become one of the most in-demand solutions for industries seeking higher efficiency, precision control and greater product differentiation.

As companies adopt smarter automation, compact devices and energy-efficient technologies, the need for tailor-made DC motors continues to grow. This article explores why custom DC motors are dominating global demand, which industries benefit most, and how engineering-driven customization can significantly enhance product performance.

What Is a Custom DC Motor?

A custom DC motor is a direct-current motor designed and engineered to meet specific application requirements. Unlike standard off-the-shelf motors, customized solutions allow manufacturers to modify:

-

Voltage & current

-

Output torque & speed

-

Gear ratio & gearbox type

-

Shaft shape and dimensions

-

Mounting structure & housing materials

-

Noise level & vibration

-

Operating environment (high temp, dust, humidity, etc.)

-

Integration with encoders, controllers or sensors

This level of engineering flexibility makes custom motors ideal for devices that demand high reliability, compact size or exact performance characteristics.

Why Custom DC Motors Are Becoming Industry Standard

1. Higher Efficiency & Optimized Performance

Custom motors can be fine-tuned to deliver maximum output with minimum power consumption. This is especially valuable in battery-powered systems and continuous-operation machinery.

2. Better Product Fit

A custom motor works seamlessly inside the customer’s device—saving space, improving structural integration and reducing assembly challenges.

3. Longer Lifespan & Lower Maintenance

When a motor is optimized for the load, environment and duty cycle, it naturally lasts longer and requires fewer repairs.

4. Competitive Advantage for Manufacturers

Brands that integrate custom DC motors often deliver smoother motion, quieter operation and higher precision, resulting in stronger market differentiation.

5. Improved System Reliability

A motor designed specifically for an application reduces the risk of overheating, overload and mismatch—common issues with universal motors.

Industries That Benefit Most From Custom DC Motors

1. Robotics & Automation

AGVs, robotic arms, collaborative robots and factory automation systems require high-torque, high-precision motion, making custom DC and BLDC motors essential.

2. Medical & Laboratory Equipment

Low-noise, high-stability motors are critical for:

-

Medical pumps

-

Respiratory devices

-

Surgical tools

-

Laboratory centrifuges

-

Dental equipment

A custom DC motor ensures compliance with strict medical performance standards.

3. HVAC, Ventilation & Air Purification

Custom DC motor with gearbox, EC blower and EC fan motor solutions help manufacturers reduce energy usage while improving airflow efficiency.

4. Smart Home Devices

Modern consumer electronics require motors that are quiet, compact and durable, such as in smart locks, curtain motors, kitchen appliances and fitness devices.

5. Industrial Machinery & Equipment

Packaging systems, conveyors, machine tools and automation lines depend on PMDC motors, gear motors and motor reducers built to match specific torque and load demands.

Custom DC Motor Types Most Commonly Requested

-

PMDC Motor (Permanent Magnet DC Motor)

-

PMDC Gear Motor

-

BLDC Motor (Brushless DC Motor)

-

High-Speed BLDC Motor

-

DC Motor with Gearbox

-

Micro DC Motor

-

EC Fan Motor / EC Blower

These can be fully customized based on torque curves, voltage, encoder options and operating conditions.

How Custom DC Motor Engineering Improves Product Performance

✔ Higher torque density

✔ Smooth start-up and accurate speed control

✔ Low noise and reduced vibration

✔ Energy savings up to 30–50%

✔ Precise matching with gear reducers

✔ Advanced materials for harsh-environment applications

✔ Custom shaft, mounting plate and housing options

This custom engineering ensures the final device performs exactly as intended—reliably, consistently and efficiently.

Choosing the Right Custom DC Motor Manufacturer

When selecting a partner, consider whether the supplier offers:

-

Professional motor design & engineering

-

Prototyping and rapid sampling

-

Full OEM/ODM customization

-

In-house gearbox, stator and rotor production

-

Quality testing (noise, torque, voltage, load, temperature)

-

Long-term supply stability

-

Strict QC system and international certifications

A reliable manufacturer can dramatically reduce development time and improve your final product quality.

Conclusion: Custom DC Motors Will Shape the Future of Smart Manufacturing

As automation, robotics and intelligent devices continue to expand globally, the demand for customized DC motors will keep growing. Manufacturers who invest in motor customization gain clear advantages: better efficiency, more precise performance and improved reliability.

Whether you’re designing industrial automation equipment or next-generation consumer electronics, a custom DC motor can elevate your product to a new level of performance and competitiveness。

Welcome to connect us, we can provide One-stop motor solution.